THE LOVE OF A CRAFT

Our raw materials undergo a rigorous selection process, our products are manufactured in 'full grain' leather, high-quality tanning, etc.

Martin leathers lose none of their flexibility and strength over time, thereby ensuring that the articles retain their shape impeccably… the 'hand-stitched' details of our articles emphasize our 'handmade' manufacturing process.

HAND MADE LEATHER CONSTRUCTION

The construction process involves:

- The choice of materials.

- The choice of tanning process, colours and textures.

- The choice of assembly.

- The choice of machine.

- The choice of expertise.

- The choice of models, combinations.

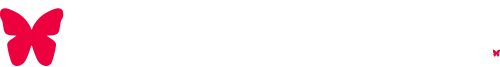

THE CHOICE OF MATERIALS

Whether it is full grain leather, split leather, reconstituted leather or high-quality tawing materials (very flexible hides used for lining collars), all the materials are used in the production of articles for animals. Synthetic components may also be used in the composition of an article. Such components are based on polypropylene, polyester and polyurethane. When combined with leather, their technical properties can be used to strengthen the product or simply give it a trendy and modern look.

Given its broad colour palette, designs and nuances, synthetic leather has the capacity to fulfil every fashion fantasy.

Crocodile or lizard, ostrich or python, deep blue or neon green, even the most well-informed will be hard-pressed to tell it from the real thing!

The use of cutting-edge technology also contributes to the aesthetic and mechanical properties. These techniques include high-frequency, flocking and transfer techniques. Every possible combination imaginable to fulfil the never ending need for originality.

THE CHOICE OF TANNING PROCESS, COLOURS AND TEXTURES.

Although synthetic products produce beautiful results, leather will remain the key raw material used in animal saddlery.

Materials that are exceptional due to the following four factors:

- The choice of tanning process.

- The choice of the finish.

- The choice of colour.

- The choice of hide.

It takes time to transform a hide into leather, that is, a strong and rot-proof material. This is a lengthy and extremely varied process, whether it involves vegetable tanning (chestnut, oak, mimosa), mineral tanning or a combination, and vegetable tanning will most often be used for strong leathers with a tight fibre structure. It produces excellent collars, which are firm in hand and do not lose their shape. Martin Sellier recommends vegetable tanning especially for the manufacturing of collars and leashes. This vegetable tanning is natural and minimises the risk of allergies.

Three parts of a hide can be used for commercial purposes.

- The shoulder, for the small sections that require character: the wrinkles of the neck will be evident on the cut article.

- The butt, for strong large-sized sections: up to 1.5 m long and 4mm thick.

- The half-back, for strong and very large-sized sections: up to 2.5 m long and 6mm thick.

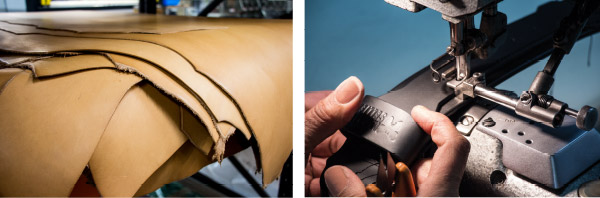

THE CHOICE OF MACHINES

The work of the saddler is primarily manual. Many operations can only be done by hand. The hand stitching, the buckles and the gluing.

A mechanical aid is necessary for mass production where this is possible: Die cutting. Skiving. Edging (creating rounded edges). Stitching. Riveting. Martin owns a fleet of very varied modern machines: die presses, skiver, sewing machine, riveting machine, stapler, etc. Given the available equipment, the workshop can create prototypes as well as small, medium and large-sized production series. The quality of work proposed is more sophisticated: fine and strong stitching, etc.

THE CHOICE OF SKILLS

Each sector has its specialist: Cutting, Sewing, Riveting ...

Martin Sellier's staff has the expertise and enthusiasm of a highly efficient production facility thanks to a know-how spanning more than 30 years.

THE CHOICE OF MODELS

Each model is defined by Martin :

- Drawing.

- Creation of prototypes.

- Creation of tools.

- Researching the best materials.

- Pre-production series.

- Production launch.